The Modern Apparel Supply Chain

In recent years, US and UK trade policies have tended to move back toward isolationism rather than collaboration. The recent wave of restrictions on global fashion production and trade has unsettled international fabric suppliers and manufacturers. Their anxieties intensified after the first wave of COVID-19, which left several factories bankrupt with fashion companies having canceled orders at the last minute or leaving suppliers unpaid and struggling as inventory in the United States failed to generate sales.

But despite this, most international clothing production centers are constantly looking for secure and long-term supplier relationships of American and British fashion brands. That’s a huge positive for fashion brands looking to build stronger, more diverse, and therefore, less risky fashion supply chains than they were relying on pre-COVID.

Fashion brands that are taking the opportunity to invest in a more diversified supply chain will find that the most effective way to manage clothing production in this era is to do it collaboratively and digitally with their vendors. That requires a strong level of partner trust, from both the manufacturers and the garment brands that employ them. Not only that, but it also mandates that independent new and mid to large clothing brands prioritize some very important supply chain practices.

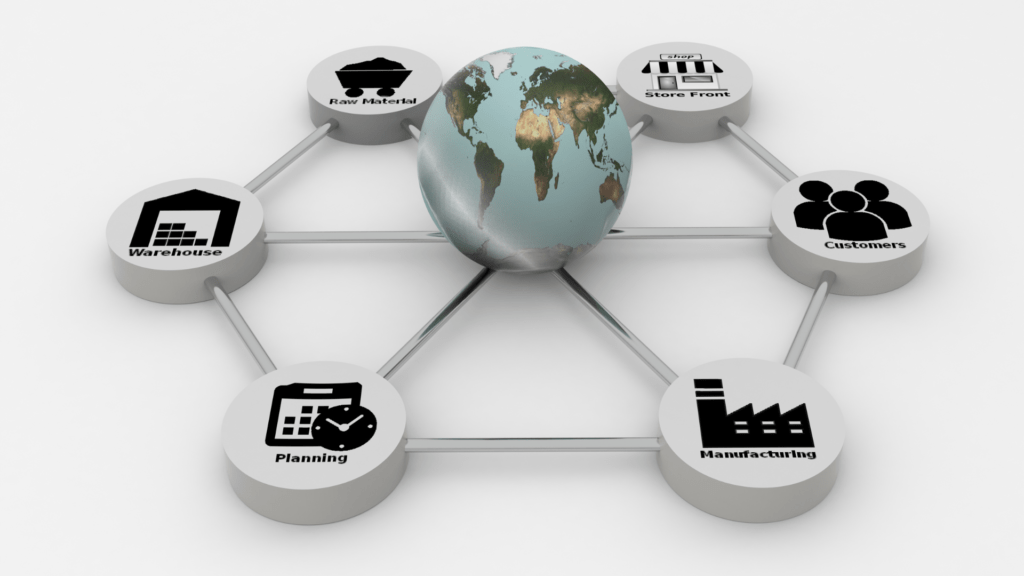

Build and Manage a Modern Apparel Supply Chain

Managing an effective supply chain in partnership with garment factories and suppliers requires fashion brands to invest in their sourcing operations in a number of ways:

Committed to efficient and high-quality inspection of factories and suppliers.

While trust has always been important in the garment industry, it becomes even more important when you enlist partners to collaborate with you on managing schedules, quality assurance and labor standards in a flawless manner. While in the past, most apparel companies relied on in-person visits to their suppliers, it is one of the most inefficient ways to check on partners. In addition, this method fails to provide uninterrupted quality control and as we have seen from the 2020 pandemic travel restrictions, it is also not always possible in times of trade crises.

Preference skills in advance.

Developing a clothing line with a diverse product offering is a challenge, but with the potential to deliver a better market share, a larger fan base and more significant profits. However, if taking that approach, fashion brands should explore partnering with multiple manufacturers, with highly specialized product expertise, instead of going with a one-size-fits-all partner.

The problem with sourcing single-factory clothing is that, not only is it a riskier supply chain strategy, but it also makes you dependent on partner factories that might produce very good quality results in one of your product categories, but deliver subpar results in another category. your other products. merchandise.

Simplify your factory-to-brand communication.

The market is full of tools for communicating fashion designs and fabric details with apparel manufacturers. However, most still remove most of the sampling and production processes from the equation, leaving product developers stuck using a patchwork of emails, WhatsApp, Excel documents, and more recently, Zoom.

Take on the challenge of having clear, traceable, and easy-to-place production communications by setting up dedicated digital tools to track and communicate supplier brand production events for your entire season inventory. The tools you adopt will ideally replace many other tools on the communications web instead of adding to the logistical clutter without providing any unique value. The best tools will also include visual proof of your product in process, as an added layer of quality control and operational transparency.