Made-to-order Fashion For Sustainability Issues

We now know that the fashion industry has had a huge waste impact on the earth. However, what solutions have we been working on so far? Of course, many people who work in the fashion industry try various things and bright ideas to change it. Because this problem occurs on our earth and has a big impact. However, it turns out that there is also an effective way to deal with sustainability issues. Even before that, namely you can apply a made-to-order fashion system!

Overproduction created “retail’s dirty little secret.”

Not only does this cost the US an estimated $50 billion a year. It destroys the planet and can cause a lot of bad news for brand. Though it’s no secret that fast fashion giants like H&M and Zara are guilty of overproduction. This does not only happened in fast-fashion brands, but also luxury brands. In 2018 Burberry came under fire after it was revealed that $38 million worth of unsold stock was sent to be burned. While many fashion businesses have attempted to address overproduction through recycling initiatives that seek to ‘make fashion circular’.

Delete dead clothes inventory

There is a reason why dead clothing supplies are considered the ‘silent killer’ of many retailers. Every dollar spent on unsold inventory is money that could be used to improve back-end systems, better talent, or more productive inventory. By shifting to the production of made-to-order garments, fashion brands can solve this problem. Michael Ball, founder of the active brand that Ultracor is made for, says his brand doesn’t keep things on their shelves. This is because there are dollars stored there that you might have to throw away.

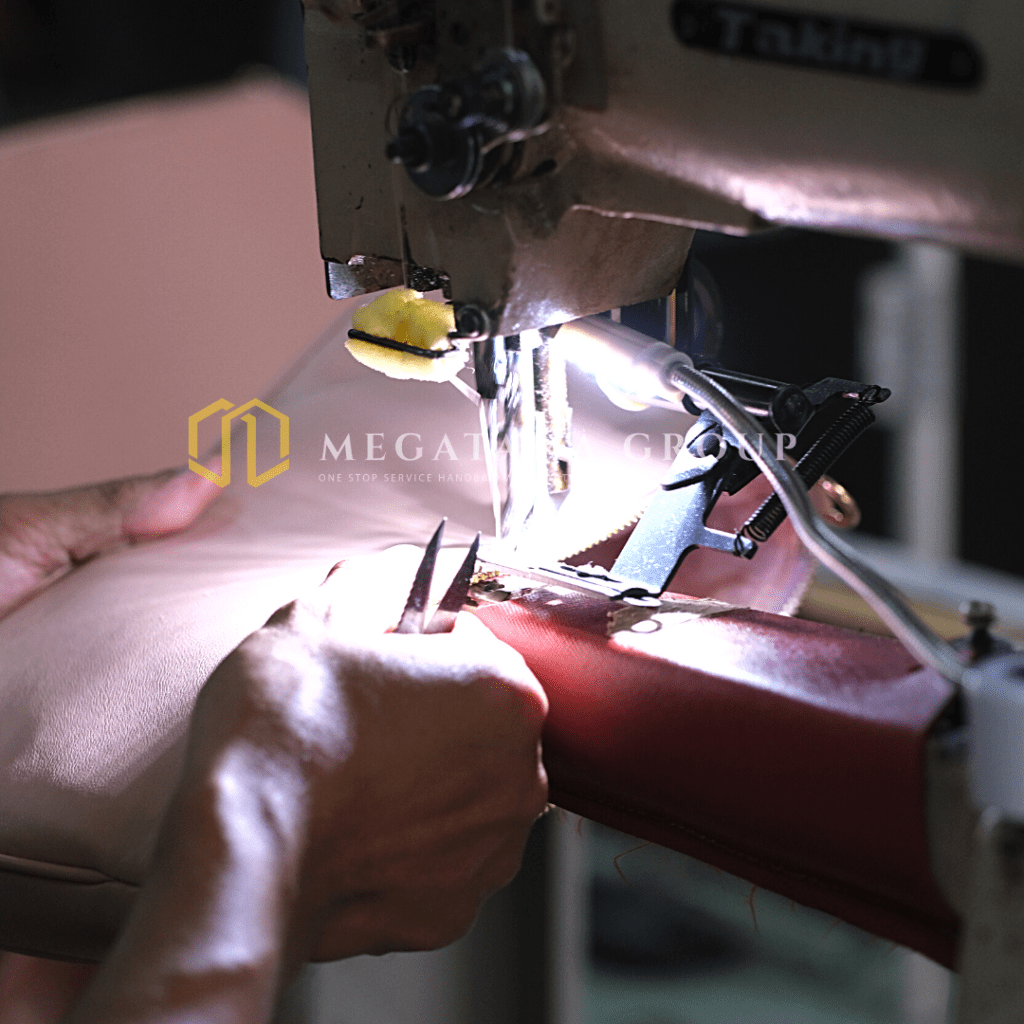

Re-emphasis on garment quality

Re-emphasis on garment quality one of the more obvious drawbacks of switching to a bespoke apparel production cycle is dealing with longer turnaround times. Brands need to pay more attention to what’s going on in their production cycle, and emphasize making quality and thoughtful goods.

The capsule collection has been around since 1985, when it was popularized by American designer Donna Karan. As a way for brands to go beyond popular trends and seasons, and bring functionality back to the fore. Many brands, such as Diesel, are trying this production cycle with a collection of experimental capsules. The brand’s new project, DIESEL UPCYCLING FOR, will release an upcoming collection of capsules every six months by a different designer. In addition, this special collection can only use recycled items for materials.

Making made-to-order modes more accessible

While many clothing brands would like to switch to a bespoke clothing production model, it can be difficult to do so without in-house manufacturing. It because so many companies won’t even produce fashion designs on a small scale. However, if your brand can’t afford the high upfront costs for the equipment and technology it needs to produce its own goods. Third-party platforms and apparel manufacturers lists can help you find manufacturers willing to bid on small quantities, low prices on minimum production runs, and save money. Your brand by making made-to-order production cycles more realistic.

If your brand is committed to quality and sustainability, switch to a bespoke production cycle today, and end unnecessary overproduction. But If you feel this system is not suitable for your brand from various aspects, you can apply it slowly. It can be from certain exclusive products!